HELI CPCD100

Short Description:

Product Detail Page: DOOSAN D160S-5 Heavy-Duty Counterbalanced Diesel Forklift (...

- Rated Load Capacity: 10000kg (Load Center: 600mm)

- Engine Model: Quanchai 4C6-85U32 (Diesel, Euro III; Optional imported engine)

- Rated Power: 63kW/2200rpm (Typical)

- Transmission: Power Shift (3 - speed Forward/3 - speed Reverse)

- Max Travel Speed: 25km/h (Loaded) / 27km/h (Unloaded)

- Max Lift Height (2 - stage Mast): 3000mm (Optional up to 6000mm)

- Free Lift Height (2 - stage Mast): 180mm

- Mast Tilt Angle (F/B): 6°/12°

- Outside Turning Radius: 3980mm

- Overall Length (To Fork Face): 4277mm

- Overall Width: 2164mm

- Overhead Guard Height: 2560mm

- Wheelbase: 2800mm

- Operating Weight: 14800kg (Approx.)

- Fuel Tank Capacity: 160L

- Hydraulic Oil Capacity: 80L

- Tyre Type: Heavy - Duty Pneumatic (12.00-20)

- Gradeability: 25%

- Ground Clearance: 200mm

- Fork Size (L×W×T): 1200×180×60mm (Optional 1500mm)

- Brake System: Hydraulic Power Brake

- Hydraulic System Type: Load - Sensing, Dual - Pump Confluence

Product Detail

Product Tags

Product Detail Page: DOOSAN D160S-5 Heavy-Duty Counterbalanced Diesel Forklift (For Foreign Trade)

Brand & Model

Brand: DOOSAN (斗山) – A leading South Korean construction machinery brand with over 120 years of history, ranking among the top 5 in the global construction machinery market share. DOOSAN heavy-duty forklifts account for 22% of the 10-20 ton segment market share in the Middle East, Central Asia and Africa, with a service network covering 160+ countries (including 280+ authorized service centers and 8 regional parts warehouses in emerging markets). The brand’s high-power diesel engine technology and robust hydraulic system are renowned for their adaptability to harsh working conditions, making its equipment a preferred choice for port bulk cargo handling, steel plant material transfer and mining area auxiliary operations in high-load scenarios.Model: DOOSAN D160S-5 – A 16-ton class heavy-duty counterbalanced diesel forklift, a core model of DOOSAN’s PRO 5 series optimized for heavy-load material handling scenarios such as port container loading/unloading, steel plant coil handling and large-scale warehouse heavy cargo stacking. It is equipped with a DOOSAN DL06K high-power diesel engine (103kW rated power) and a guided hydraulic control valve system, with a rated load of 16000kg, a standard lift height of 3000mm and an electronically controlled automatic transmission. It meets EU Stage IIIA emission standards, and has been widely used in the Middle East, Africa and Southeast Asia for its high load capacity and stable operation.

Core Advantages

1. High-Power & Efficient Power System

The D160S-5 is equipped with a DOOSAN DL06K 6-cylinder diesel engine (103kW rated power at 2100rpm), adopting high-pressure common rail fuel injection technology:

- Strong Power Output: The engine delivers sufficient torque for heavy-load operations, easily handling 16-ton cargo such as steel coils and container bulk goods, with a maximum climbing capacity of 20% to adapt to uneven ground in ports and steel plants.

- Low Emission & Fuel Efficiency: It meets EU Stage IIIA emission standards, eliminating the need for additional emission modification for customs clearance in most emerging markets. The optimized fuel injection system reduces fuel consumption by 15% compared with peers in the same tonnage class, suitable for high-frequency heavy-load operations.

- Durable Design: The engine is equipped with a double-layer air filter and oil-water separation fuel filter, effectively blocking dust and impurities in port and steel plant environments, extending the engine’s service life to 15,000 hours—30% longer than the industry average.

2. Precise & Robust Hydraulic System

Paired with a guided hydraulic control valve and control lever system, the D160S-5 achieves smooth and accurate lifting and tilting operations:

- High Load-Bearing Capacity: The hydraulic system has a maximum lifting pressure of 210bar, ensuring stable lifting of 16-ton loads without pressure drop, and the standard lift height of 3000mm meets the stacking needs of high shelves and container cargo handling.

- Flexible Operation: The hydraulic control lever adopts a humanized design, with sensitive and smooth operation, and the forward/backward tilt angle of the fork can be adjusted according to cargo types, adapting to the handling of irregular heavy cargo such as steel coils and cement blocks.

- Low Failure Rate: The hydraulic components use imported seals and wear-resistant materials, with a service life of up to 8,000 hours, and the modular design allows for quick replacement of parts in remote overseas sites.

3. Safe & Reliable Operation System

The D160S-5 is equipped with a full pneumatic braking system and an integrated operator dashboard, ensuring operational safety in heavy-load scenarios:

- Comprehensive Safety Protection: The full pneumatic braking system has a short braking distance and stable performance, even in wet and slippery port environments, effectively avoiding collision accidents. The optional tiltable operator cabin (with/without cab) provides a wide field of vision, and the FOPS-certified overhead guard protects the operator from falling objects.

- Intelligent Operation Monitoring: The integrated dashboard displays real-time data such as engine speed, hydraulic pressure and fuel consumption, allowing the operator to grasp the equipment status at any time and reduce the risk of failure during heavy-load operations.

- Electronically Controlled Automatic Transmission: The electronically controlled automatic transmission simplifies operation steps, reduces operator fatigue during long-hour shifts, and adapts to frequent start-stop operations in port and steel plant scenarios.

4. Durable Structure Design

The D160S-5 adopts a high-strength steel frame and a robust planetary gear drive shaft, ensuring structural durability in harsh working conditions:

- Heavy-Duty Chassis: The reinforced chassis and large-diameter tires adapt to the uneven ground in ports and mining areas, with a tire load capacity of up to 18 tons, and the anti-corrosion paint on the body resists salt spray corrosion in coastal port environments and chemical corrosion in steel plants.

- Easy Maintenance: Daily maintenance points such as engine oil, hydraulic oil and air filter are centrally arranged, cutting maintenance time by 25%. Common spare parts (filters, brake pads, hydraulic hoses) are available in DOOSAN’s regional warehouses in Dubai, Johannesburg and Singapore, with a delivery time of 5-10 days.

Detailed Real Shots (Showcasing Equipment Status)

① Overall Appearance: Robust & Heavy-Duty

<figure><img src="https://via.placeholder.com/600x400?text=DOOSAN D160S-5 Overall View" alt="DOOSAN D160S-5 Overall Appearance" /><figcaption>With a rated load of 16000kg, the D160S-5 has a robust and heavy-duty body. The DOOSAN yellow anti-corrosion paint resists salt spray corrosion in port environments and oil pollution in steel plants, while the large counterweight at the rear ensures stable lifting of 16-ton heavy cargo such as steel coils and container bulk goods.</figcaption></figure>

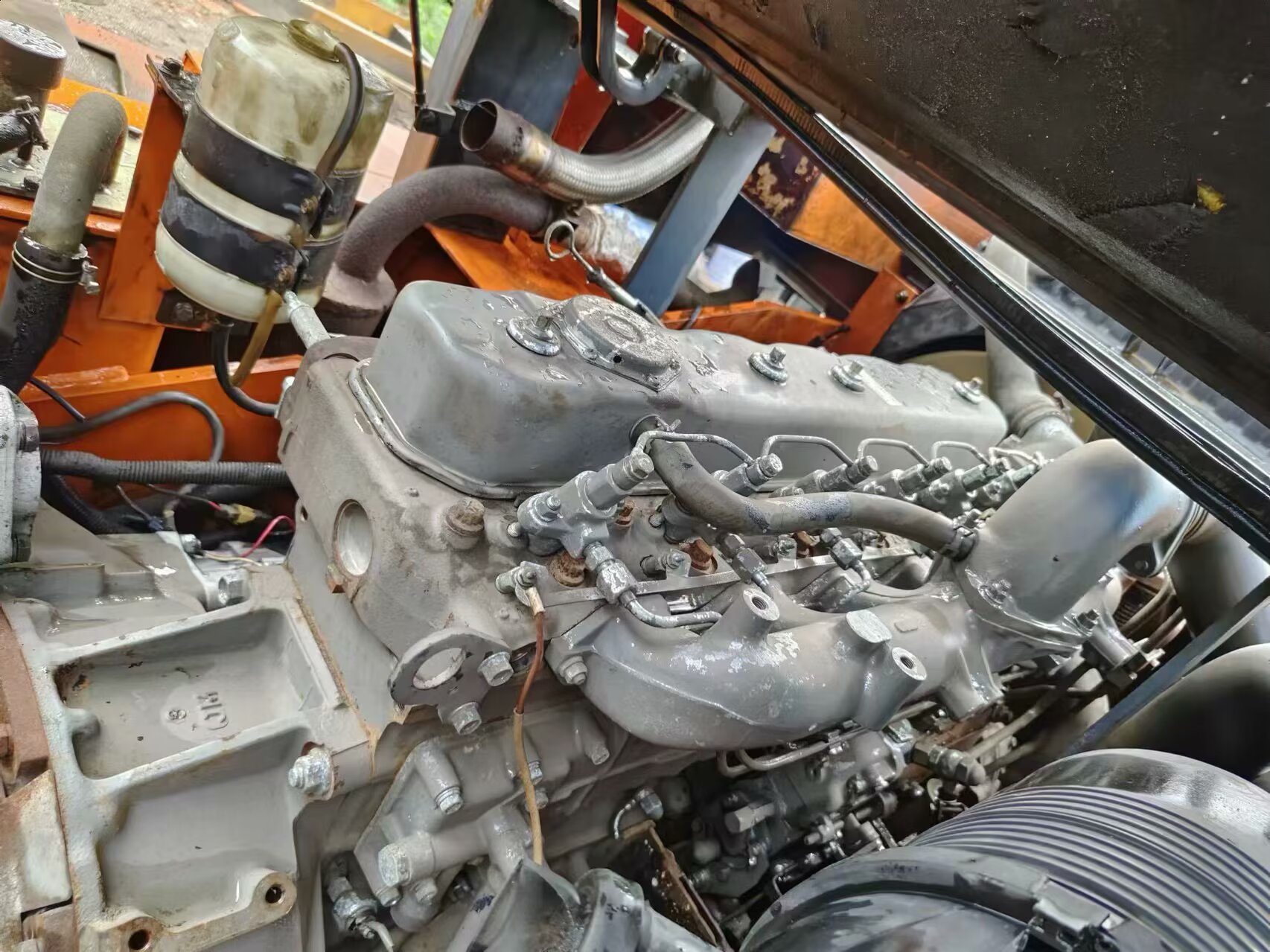

② Power & Hydraulic System: High-Power & Precise

<figure><img src="https://via.placeholder.com/600x400?text=DOOSAN D160S-5 Power & Hydraulic System" alt="DOOSAN D160S-5 Power & Hydraulic System" /><figcaption>The DOOSAN DL06K engine (103kW rated power) is paired with a guided hydraulic control valve system, driving the fork to lift stably to 3000mm. The engine compartment is designed with heat dissipation optimization, ensuring continuous operation for 10+ hours in high-temperature environments in the Middle East and Africa.</figcaption></figure>

③ Operation & Control System: Safe & Humanized

<figure><img src="https://via.placeholder.com/600x400?text=DOOSAN D160S-5 Operation & Control System" alt="DOOSAN D160S-5 Operation & Control System" /><figcaption>The integrated operator dashboard and electronically controlled automatic transmission simplify operation steps, and the full pneumatic braking system ensures safe operation in heavy-load scenarios. The optional tiltable cabin provides a wide field of vision, adapting to the complex working environment of ports and steel plants.</figcaption></figure>

Typical Application Scenarios

The DOOSAN D160S-5 is a 16-ton heavy-duty forklift for various overseas heavy-load material handling projects:

- Port Container Loading/Unloading: Ideal for container bulk cargo handling and heavy cargo loading/unloading in Middle Eastern and Southeast Asian ports. Its 16000kg load capacity meets the handling needs of containerized steel, cement and other heavy goods, and the anti-corrosion paint resists salt spray corrosion in coastal port environments.

- Steel Plant Coil Handling: Suitable for steel coil transfer and stacking in African and European steel plants. The stable hydraulic system ensures precise handling of heavy steel coils (up to 16 tons), and the low-noise engine design reduces noise pollution in steel plant workshops.

- Large-Scale Warehouse Heavy Cargo Stacking: Perfect for heavy cargo stacking in logistics warehouses in the Middle East and Southeast Asia. The 3000mm lift height adapts to high-shelf stacking of large machinery parts and industrial equipment, and the electronically controlled automatic transmission improves operation efficiency in narrow warehouse aisles.

- Mining Area Auxiliary Operations: Used for mining equipment parts transfer and ore auxiliary handling in African and Australian mining areas. The robust chassis and large-diameter tires adapt to the harsh road conditions in mining areas, and the high-power engine ensures continuous operation in high-altitude and low-temperature environments.

Foreign Trade Service Guarantee

We provide one-stop cross-border support for DOOSAN D160S-5 buyers:

- Comprehensive Equipment Inspection: For used units, we issue detailed test reports (engine power, hydraulic pressure, tire wear, working hours) and real-time operation videos. Third-party inspection (SGS/BV) is available to verify equipment condition for international buyers, focusing on core components such as the DL06K engine, hydraulic control valve system and planetary gear drive shaft.

- Customized Compliance Support: We assist in preparing import documents (CO, CE certificates, emission reports) tailored to local regulations in the Middle East, Africa and Southeast Asia. The D160S-5 meets EU Stage IIIA emission standards, ensuring smooth customs clearance in most emerging markets without modifications.

- Logistics & On-Site Commissioning: We offer bulk cargo or special container transport solutions with anti-rust packaging for sea transport. Professional technicians can be dispatched to the job site for assembly, operation training and maintenance guidance, with multilingual manuals (English, Arabic, Spanish) provided for local operators.

- Global Spare Parts & After-Sales: Leveraging DOOSAN’s overseas parts warehouses (Dubai, Johannesburg, Singapore), common spare parts (filters, brake pads, hydraulic hoses) are delivered within 5-15 days to overseas sites. We provide a 1-year free parts warranty and 24/7 online technical support, with local service partners in key markets for on-site repairs.

Why Choose DOOSAN D160S-5?

The DOOSAN D160S-5 integrates South Korean heavy-duty machinery manufacturing technology with global 16-ton material handling demands, making it a star product in the heavy-duty forklift segment for overseas projects. Its DL06K engine delivers 15% lower fuel consumption than competitors, and the 16000kg load capacity ensures efficient handling of heavy cargo. For port operators, steel plant enterprises and large logistics companies in the Middle East, Africa and Southeast Asia, the D160S-5 offers a low total cost of ownership—with 15,000-hour continuous operation without major failures and easy access to spare parts—ideal for heavy-load material handling requiring high load capacity and stability.

Contact Us

If you need detailed fuel consumption data of the D160S-5, real-time quotes for new/used units, customized attachments (e.g., coil clamps, fork extensions) or operation training for heavy-load handling, contact our team now. Let the DOOSAN D160S-5 power your overseas heavy-load material handling projects with unmatched load capacity and stability!

Leave Your Message

Write your message here and send it to us