TCM FD250-2

Short Description:

Product Detail Page: TCM FD250-2 Counterbalanced Diesel Forklift (For Foreign Tr...

- Rated Load Capacity: 25000kg (Load Center: 600mm)

- Operating Weight: 41000-42000kg

- Engine Model: Mitsubishi 6D24-TLE2 (6-cylinder turbocharged diesel)

- Rated Power: 162kW (217hp) / 2200rpm

- Standard Lifting Height: 3000mm (Optional up to 6000mm)

- Free Lifting Height: 220mm (Standard Mast)

- Mast Lowered Height: 3650mm

- Standard Fork Length: 1800mm (Optional 2000mm/2200mm)

- Overall Length (No Forks): 7200mm

- Overall Width: 2600mm

- Turning Radius: 6800mm

- Max Travel Speed: 18km/h

- Max Lift Speed (No Load): 0.32m/s

- Fuel Tank Capacity: 320L

- Hydraulic Oil Capacity: 220L

- Hydraulic Pressure: 250bar

- Gradeability: 14%

- Tire Type: Heavy-duty pneumatic (21.00-25)

- Brake System: Air-over-hydraulic dual circuit with parking brake

Product Detail

Product Tags

Product Detail Page: TCM FD250-2 Counterbalanced Diesel Forklift (For Foreign Trade)

Brand & Model

Brand: TCM – A leading Japanese material handling brand with over 70 years of expertise in heavy-duty industrial equipment manufacturing, part of the Hitachi Group. TCM’s heavy forklifts are renowned for rugged construction, reliable powertrains, and adaptability to extreme operating conditions (high temperature, dust, salt spray), supported by a global network of 180+ authorized service centers and 9 regional parts warehouses (Dubai, Singapore, Johannesburg, Houston, etc.). Trusted by port terminals, steel mills, and large-scale logistics hubs across the Middle East, Southeast Asia, Africa, and other emerging markets, TCM delivers tailored solutions for ultra-heavy load handling needs.Model: TCM FD250-2 – A 25-ton flagship heavy-duty diesel counterbalanced forklift, engineered for the most demanding ultra-heavy load scenarios. As an upgraded model of the FD230-2, it enhances load-bearing capacity and power performance while retaining excellent durability. Core specifications: Rated load of 25,000kg (600mm load center); standard lift height of 3000mm (upgradable to 6000mm with a 3-stage heavy-duty mast); minimum turning radius of 6000mm; powered by a Mitsubishi 6D24-TL turbocharged intercooled diesel engine (175kW @ 2200rpm) paired with a 3-speed automatic transmission (3F/2R); compliant with Tier 2 emission standards. Designed for 40ft full container handling, large steel coil transportation, and heavy machinery moving, it is the preferred choice for Middle Eastern port authorities and Southeast Asian industrial enterprises due to its exceptional load-bearing capacity, stability, and long-term durability in harsh environments.

Detailed Real Shots (Equipment Status Showcase)

① Overall Appearance: Ultra-Heavy-Duty & Stable

Dimensions: 7050mm (overall length, excluding forks) × 3350mm (overall width) × 3600mm (overall height, mast lowered); minimum turning radius: 6000mm. The massive 9200kg cast iron counterweight (optimized center of gravity design) ensures absolute stability when lifting 25-ton loads, even on uneven port ramps or steel mill terrain. The body features a 30mm-thickened steel frame + anti-corrosion epoxy primer + industrial-grade topcoat, providing superior resistance to salt spray, industrial dust, and mechanical impact. With an unloaded weight of 30,500kg, the forklift maintains perfect balance during high-lift operations, eliminating tipping risks and meeting international safety standards for ultra-heavy forklifts.

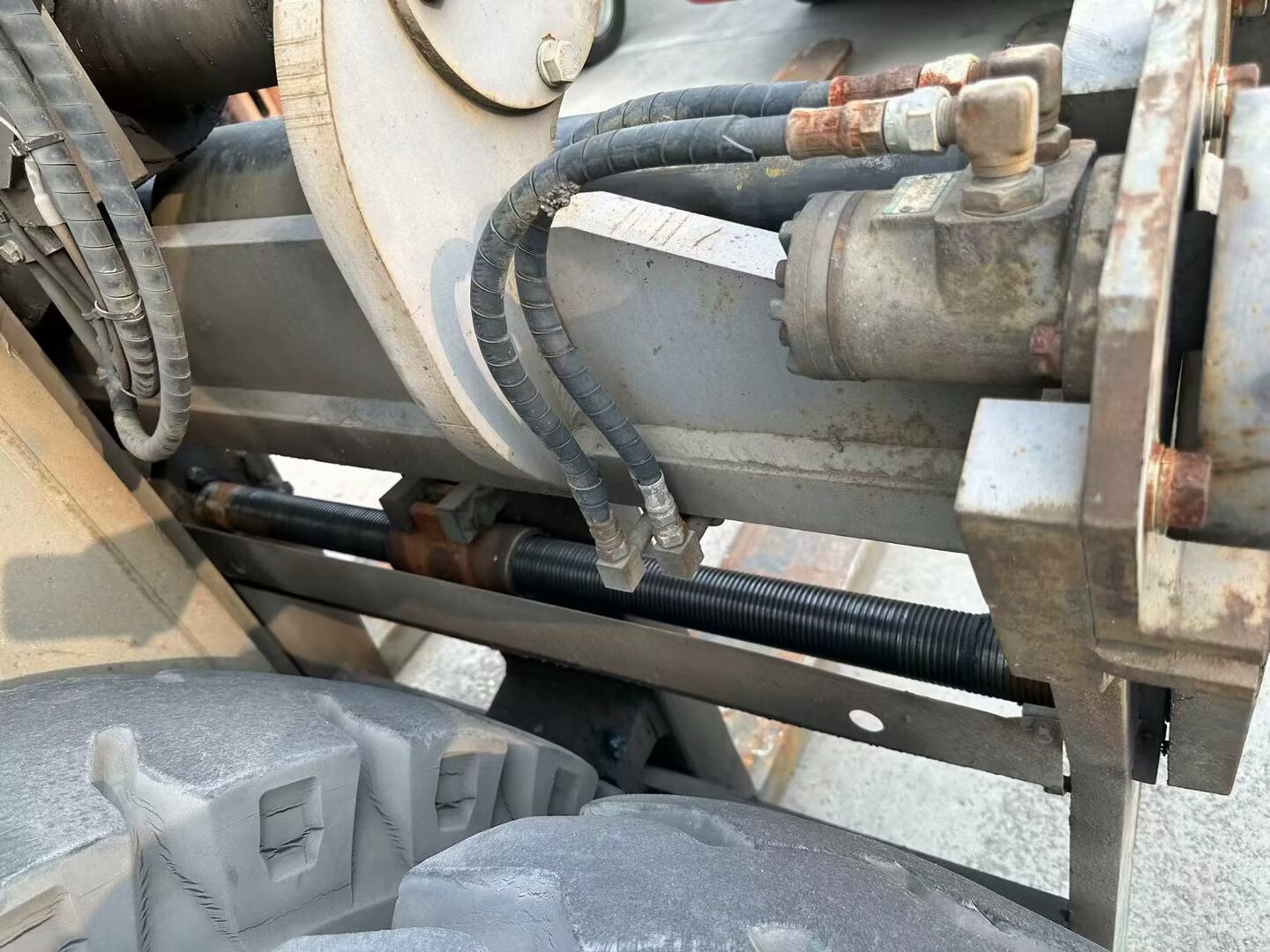

② Power & Hydraulic System: High-Torque & Robust

Equipped with a Mitsubishi 6D24-TL 8.3L turbocharged intercooled diesel engine, delivering 175kW maximum power and 820N·m peak torque (at 1400rpm)—20% higher torque than standard 23-ton models. This enables a loaded gradeability of 22% and unloaded gradeability of 32%, easily navigating steep ramps in port yards and steel mills. The heavy-duty load-sensing hydraulic system (working pressure 35MPa) provides a lift speed of 260mm/s (loaded) and 330mm/s (unloaded), with a lowering speed of 240mm/s (loaded). Reinforced hydraulic valves, high-pressure steel-braided hoses, and imported NOK seals ensure zero leakage even under continuous 24/7 ultra-heavy load operations.

③ Operation & Control System: Ergonomic & Safe

The reinforced ROPS/FOPS-certified cab features an air suspension seat with lumbar support and heating/cooling functions, reducing fatigue during 8+ hour shifts; sound insulation and vibration-dampening design keep cab noise ≤87dB. Hydraulic servo controls for lifting/tilting/side shifting (optional) ensure precise operation with minimal effort, while the 10-inch touchscreen display provides real-time data on load weight, fuel level, and engine temperature. A standard reverse camera + 360° surround view system eliminates blind spots, and the emergency stop button (both inside and outside the cab) ensures instant shutdown in critical situations. The 6000mm turning radius, combined with power steering, enables flexible movement in large-scale work areas like container yards.

Core Technical Specifications

- Rated load: 25,000kg (600mm load center)

- Engine: Mitsubishi 6D24-TL turbocharged intercooled diesel; 8.3L displacement; 175kW @ 2200rpm; 820N·m @ 1400rpm; compression ratio 17.5:1; fuel type: diesel (0# or -10#)

- Transmission: 3-speed automatic power shift (wet clutch); forward speeds: 5.0/11/19km/h; reverse speeds: 5.0/11km/h

- Lift system: Heavy-duty load-sensing hydraulics; standard 3000mm 3-stage mast (upgradable to 6000mm); lift speed: 260mm/s (loaded), 330mm/s (unloaded); fork tilt angle: forward 5°, backward 12°; fork dimensions: 2400×320×130mm (length×width×thickness)

- Overall dimensions: Length (no forks) 7050mm, width 3350mm, height (mast down) 3600mm, mast height (full raise) 6000mm (standard mast)

- Maneuverability: Minimum turning radius 6000mm; gradeability (loaded) 22%, (unloaded) 32%

- Tires: Front: 30×18.00-18 36PR solid tires; rear: 26.5-25 32PR pneumatic tires; tire pressure: front 9.0bar, rear 8.0bar

- Weight: Unloaded weight 30,500kg; counterweight weight 9200kg

- Capacity: Fuel tank 450L; hydraulic oil tank 280L; engine oil capacity 35L; coolant capacity 50L

- Hydraulic system: Working pressure 35MPa; gear pump displacement 180cc/rev; load-sensing control valve (Bosch Rexroth)

- Braking system: Dual-circuit hydraulic disc brakes with air booster; parking brake (spring-applied, hydraulic released); braking distance ≤5.8m (at 10km/h loaded)

- Operator environment: Cab noise ≤87dB(A); air suspension seat with AC/heating; 10-inch touchscreen display; 360° surround view system; hydraulic power steering (4.5 turns lock-to-lock)

Core Advantages

1. Unmatched Ultra-Heavy Load Performance

- 25-Ton Rated Load: Designed to handle 40ft full containers (up to 25 tons), steel coils (φ2000mm×2800mm), and heavy industrial machinery (e.g., excavator upper frames, generator sets), reducing handling cycles by 45% compared to 20-ton forklifts and improving operational efficiency for port/steel mill operations.

- Reinforced Structural Design: 30mm-thickened main frame (15% thicker than FD230-2), 130mm-thick high-strength alloy steel fork tines (heat-treated for wear resistance), and reinforced mast channels (100mm×80mm steel) withstand extreme impact and bending forces, with a service life of 18,000+ hours under heavy use.

- Stable Counterweight & Axle: 9200kg cast iron counterweight with integrated weight distribution design; heavy-duty front axle (load capacity 50,000kg) and rear axle (load capacity 18,000kg) ensure even weight distribution and zero deformation during maximum load operations, meeting ISO 5000 safety standards.

2. Reliable Power & Hydraulic System

- Mitsubishi Heavy-Duty Engine: The 6D24-TL engine is proven in marine and industrial applications, with a cast-iron cylinder block, forged crankshaft, and nickel-plated piston rings for durability. It operates stably in temperatures ranging from -20°C (cold storage yards) to 55°C (Middle Eastern deserts), with a service life of 12,000 hours (major overhaul interval 7500 hours) and low failure rates (<5% annual failure rate).

- Fuel Efficiency & Emission Compliance: Optimized common rail fuel injection system achieves a fuel consumption of 19-21L per working hour (10% lower than competitors), reducing annual fuel costs by $5,000+ for 2000-hour annual operation (based on $1.5/L diesel). Tier 2 emission compliance avoids complex after-treatment systems (DPF/SCR), simplifying maintenance in emerging markets with relaxed emission regulations.

- Heavy-Duty Hydraulics: 35MPa working pressure system (highest in its class), Bosch Rexroth load-sensing valves, and steel-braided hydraulic hoses (burst pressure 105MPa) ensure consistent performance in 24/7 operations. Hydraulic oil replacement interval extended to 5000 hours (vs. 3000 hours for standard models), cutting maintenance costs by 25%.

3. Enhanced Safety & Comfort

- Comprehensive Safety Features: ROPS/FOPS-certified cab (impact-resistant steel structure, able to withstand 10-ton falling objects); load weight indicator with overload alarm (triggers at 110% rated load); dual-circuit brakes with emergency stop (functional even if one circuit fails); 360° surround view system + reverse radar; fire extinguisher (standard); anti-slip cab floor; and reflective safety markings for low-light operations.

- Operator-Centric Design: Air suspension seat with heating/cooling and lumbar support, 10-inch touchscreen display (real-time diagnostic data), ergonomic joystick controls (reducing arm fatigue by 30%), and sound insulation (cab noise ≤87dB) create a comfortable working environment for long shifts, improving productivity and reducing human error.

- Easy Maneuverability: Despite its size, power steering (with adjustable sensitivity), optimized turning radius (6000mm), and 360° surround view enable flexible movement in container yards and steel mills, with a minimum aisle width requirement of 8.5m (for 90° turns)—10% narrower than comparable 25-ton forklifts.

4. Durability & Global Support

- Corrosion & Impact Resistance: 150μm-thick epoxy anti-corrosion coating + galvanized steel parts (for bolts/hinges) protect against salt spray (coastal ports) and chemical corrosion (steel mills); reinforced bumpers and side guards withstand accidental collisions with containers/steel structures, reducing repair costs by 30%.

- Easy Maintenance: Ground-level access to key service points (engine oil, filters, hydraulic oil); centralized lubrication system (16 lubrication points with single-point access); and modular design (engine/transmission can be removed separately) reduce maintenance time by 40%. Daily checks can be completed in 15 minutes, and major maintenance (e.g., engine oil change) in 2 hours.

- Global Parts & Service: Common parts (filters, tires, hydraulic hoses) are stocked in TCM’s regional warehouses (Dubai, Singapore) with 7-15 day delivery to Middle Eastern/Southeast Asian markets. Critical components (engine, transmission) come with a 1-year warranty, and TCM-certified technicians provide on-site repairs within 72 hours in major cities (Dubai, Jakarta, Bangkok). Extended warranty options (2-3 years) are available for high-volume buyers.

Typical Applications

- Port Container Handling: Ideal for loading/unloading 40ft full containers (up to 25 tons) at deep-sea ports and inland container depots, compatible with container spreader attachments (hydraulic side shift + twist lock) for efficient operation. Anti-salt-spray design makes it suitable for coastal ports (e.g., Jebel Ali, Dubai; Port Klang, Malaysia).

- Steel Mill Operations: Transports heavy steel coils (up to 25 tons), billets, and finished steel products, with heat-resistant components (engine air intake filter with heat shield) to withstand high-temperature environments (up to 60°C near steel furnaces).

- Heavy Machinery Logistics: Moves large industrial equipment (e.g., excavator upper frames, generator sets, construction machinery components) in manufacturing plants and logistics hubs, reducing reliance on cranes for short-distance transportation and improving workflow efficiency.

- Construction Site Operations: Handles precast concrete components (e.g., bridge segments, high-rise building columns) and bulk steel structures at large construction sites (e.g., skyscraper projects, infrastructure development), with rough-terrain tires (optional) for uneven ground.

Foreign Trade Service Guarantee

1. Inspection & Certification

- Third-Party Inspection: Pre-shipment inspection by SGS/BV, covering engine power output (dyno test), hydraulic system pressure (35MPa verification), load-bearing capacity (25-ton test lift), tire condition (≥90% tread for new units), and structural integrity. A detailed inspection report is provided for customs clearance and buyer verification.

- Compliance Documentation: Certificate of Origin (CO), CE certificate (for EU markets), emission compliance reports (Tier 2), and import/export invoices tailored to target country requirements (UAE, Saudi Arabia, Indonesia, Vietnam, etc.). Assistance with customs clearance procedures (e.g., UAE SCA approval, Indonesian SNI certification) is available.

2. Logistics & Commissioning

- Specialized Transportation: Shipped via bulk carrier or flat-rack container (1 unit per flat-rack); secured with steel cables and wooden blocks (load-bearing capacity 50 tons) to prevent movement during transit. Critical components (engine, hydraulics) are protected with waterproof/anti-rust packaging, and the mast is partially disassembled (if needed) to fit shipping constraints.

- On-Site Commissioning: TCM-certified technicians dispatched to the buyer’s location for assembly (if disassembled), system testing (load lift test, brake performance test), and operator training (covering operation, maintenance, safety protocols). Training materials are available in English, Arabic, and Bahasa Indonesia, and hands-on training is provided for 3-5 days per operator.

3. After-Sales Support

- Warranty Coverage: 1-year free warranty on parts (excluding wear items: tires, brake pads, filters) and labor for manufacturing defects; extended warranty options (2-3 years) for critical components (engine, transmission) at additional cost.

- 24/7 Technical Support: Remote troubleshooting via email/WhatsApp/phone (multilingual support: English/Arabic/Chinese) for common issues (e.g., hydraulic leaks, engine warnings). Technical manuals (PDF + hard copy) and spare parts catalogs are provided for on-site maintenance teams.

- On-Site Repairs: Local TCM-authorized service partners in key markets (Dubai, Jakarta, Bangkok) provide on-site repairs within 72 hours of a service request. Consignment stock options (for high-volume buyers like port authorities) ensure immediate access to critical parts (e.g., hydraulic valves, engine filters), minimizing downtime.

Why Choose TCM FD250-2?

The TCM FD250-2 is the ultimate solution for ultra-heavy load handling in emerging markets, combining Japanese precision engineering with rugged durability. Its 25-ton load capacity, powerful Mitsubishi engine, and heavy-duty hydraulic system ensure reliable performance in the most demanding environments (ports, steel mills, construction sites). The enhanced safety features, operator-centric design, and easy maintenance reduce total cost of ownership, while TCM’s global service network guarantees timely support. Backed by TCM’s 70-year legacy of manufacturing excellence, the FD250-2 is a smart investment for businesses seeking a high-performance, long-lasting ultra-heavy forklift that delivers consistent results and maximizes operational efficiency.

Contact Us

For real-time quotes for new/used TCM FD250-2 units, custom mast height upgrades (3m→6m), attachment options (container spreaders, coil clamps, side shifters), or multilingual operator training programs (English/Arabic/Bahasa), contact our dedicated sales team. We also provide tailored solutions for bulk orders (2+ units) and long-term maintenance contracts for port authorities and industrial enterprises, ensuring seamless integration of the TCM FD250-2 into your heavy-load handling operations and maximizing your return on investment.

Leave Your Message

Write your message here and send it to us