DOOSAN DX225LC-9C

Short Description:

DOOSAN DX225LC-9C 22.5-Ton Hydraulic Excavator - Foreign Trade Sales CopyBrand &...

- Rated Operating Weight: 21,800 kg (21.8 Ton)

- Standard Bucket Capacity: 1.05 m³ (optional 1.2 m³)

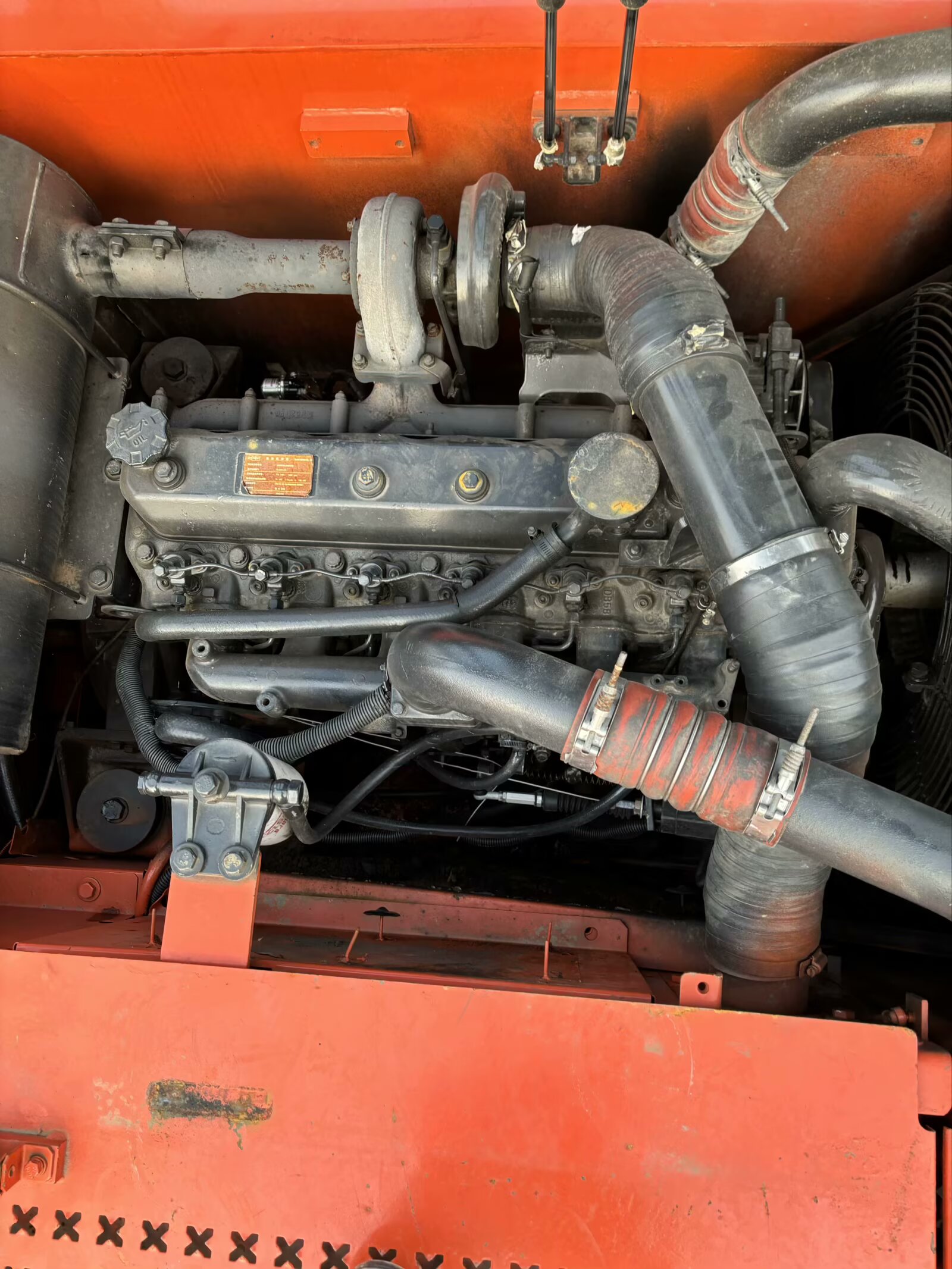

- Engine Model: Doosan DL06 (6-cylinder turbo diesel)

- Rated Power: 115 kW / 1,900 rpm (157 HP)

- Max. Digging Depth: 6,592 mm

- Max. Digging Reach (Ground): 9,873 mm

- Max. Dumping Height: 6,830 mm

- Hydraulic System Pressure: 34.3 MPa

- Main Pump Flow: 2×210.6 L/min

- Travel Speed (High/Low): 5.7 km/h / 3.1 km/h

- Swing Speed: 10.5 rpm

- Gradeability: 35%

- Ground Pressure: 44 kPa

- Bucket Digging Force: 152 kN

- Arm Digging Force: 108 kN

- Fuel Tank Capacity: 400 L

- Hydraulic Oil Capacity: 195 L

- Overall Transport Dimensions (L×W×H): 9,506×2,990×2,891 mm

- Undercarriage Track Width: 600 mm

- Track Gauge: 2,390 mm

Product Detail

Product Tags

DOOSAN DX225LC-9C 22.5-Ton Hydraulic Excavator - Foreign Trade Sales Copy

Brand & Model Positioning

Brand: Doosan – A leading South Korean heavy equipment manufacturer with over 50 years of excavator R&D and production expertise, renowned for rugged construction, high operational efficiency, and cost-effective after-sales support. Doosan excavators are trusted by construction, mining, and infrastructure enterprises across the Middle East, Southeast Asia, and Africa, dominating the mid-tonnage excavator market with their adaptability to harsh working environments.Model: DOOSAN DX225LC-9C – A 22.5-ton premium hydraulic crawler excavator, the flagship model of Doosan’s 9C series, engineered for medium-to-large-scale earthmoving, foundation excavation, and rock crushing tasks. Equipped with a Doosan DL06P common rail diesel engine and a closed-center load-sensing hydraulic system, it balances powerful digging force, fuel efficiency, and operator comfort, ideal for urban construction, road construction, and quarry operations.

Core Technical Specifications

- Operating Weight: 22,800kg

- Engine: Doosan DL06P 6-cylinder turbocharged intercooled diesel engine; rated power 129kW @ 2000rpm; peak torque 650N·m @ 1400rpm; fuel consumption 18-22L/h; compliant with Tier 2/EU Stage II emission standards (suitable for emerging markets with relaxed emission regulations)

- Working Device: Standard 1.2m³ heavy-duty bucket (high manganese steel wear-resistant plate); maximum digging depth 6.4m; maximum digging radius 9.9m; maximum dumping height 6.8m; bucket digging force 158kN; arm digging force 112kN

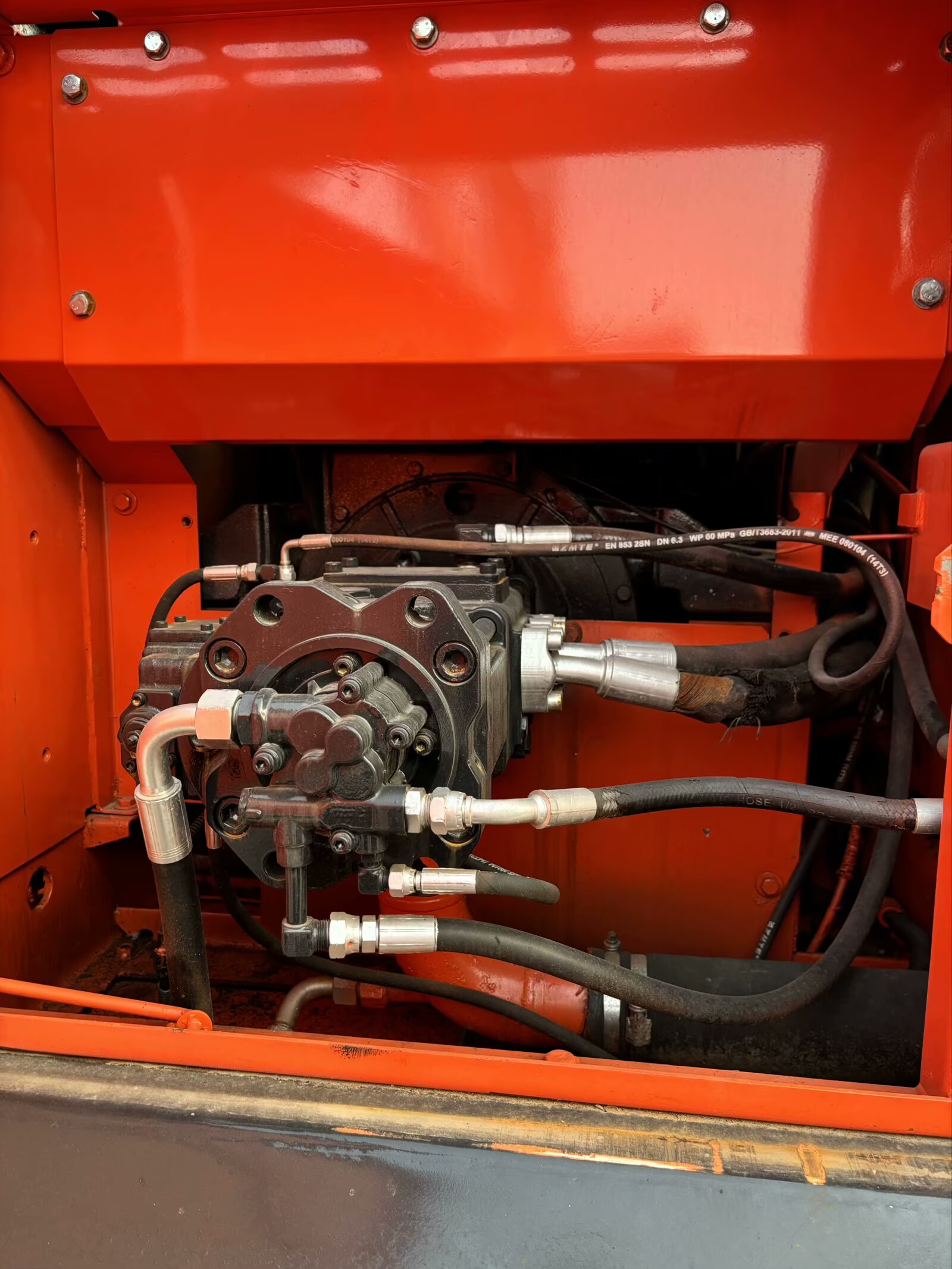

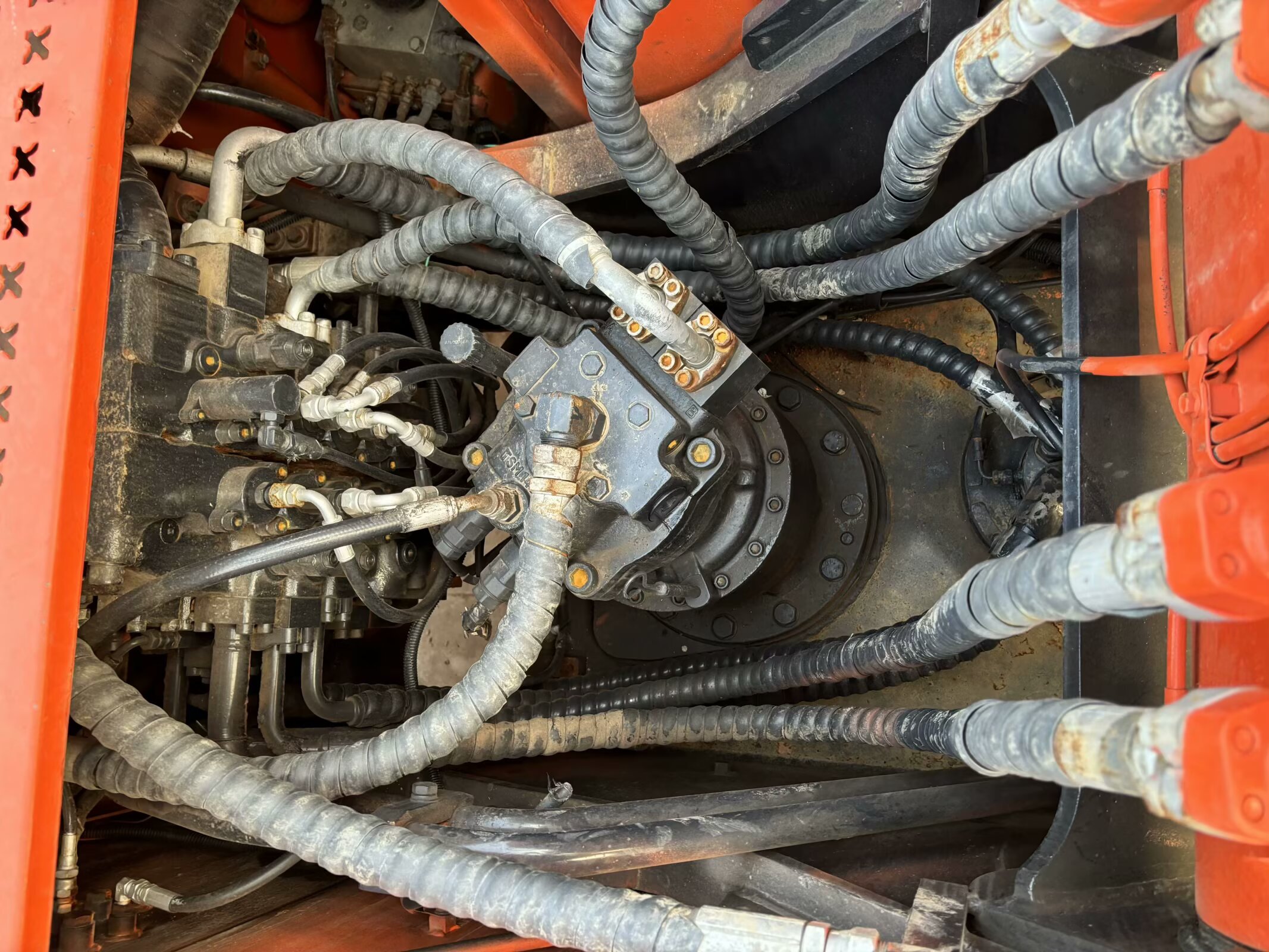

- Hydraulic System: Closed-center load-sensing (CLSS) hydraulic system; working pressure 34.3MPa; main pump displacement 2×123cc/rev; swing speed 12.5rpm; travel speed (low/high) 3.2/5.5km/h

- Undercarriage: Track shoe width 600mm; track ground contact length 3,200mm; ground pressure 44.1kPa; reinforced track frame and idler for rough terrain operation

- Operator Cab: ROPS/FOPS certified; air suspension seat with lumbar support; air conditioning (standard); 8-inch color LCD monitor; cab noise ≤72dB(A); ergonomic joystick control

- Fuel & Fluid Capacities: Fuel tank 320L; hydraulic oil tank 150L; engine oil capacity 18L; coolant capacity 25L

Core Advantages

1. Powerful Digging Performance & Versatility

- 158kN Bucket Digging Force: Delivers strong penetration in hard soil and rock layers, reducing cycle time for earthmoving tasks by 15% compared to peer models. The 1.2m³ large-capacity bucket increases single-cycle loading efficiency, ideal for bulk earthmoving and quarry material handling.

- Multiple Working Modes: 3 selectable operation modes (Power/Standard/Economy) to adapt to different working conditions—Power mode for heavy rock crushing, Economy mode for fuel-saving light-load operations, and Standard mode for balanced daily construction tasks.

- Wide Range of Attachments: Compatible with hydraulic breakers, grapples, thumb buckets, and grading blades, expanding application scenarios from earthmoving to demolition, material sorting, and slope grading.

2. Reliable Power & Fuel Efficiency

- Doosan DL06P Engine: The common rail fuel injection system optimizes fuel atomization, improving combustion efficiency and reducing fuel consumption by 10% compared to the previous generation model. The engine’s dust-proof air intake system and heat-resistant design ensure stable operation in dusty deserts and high-temperature tropical regions.

- CLSS Hydraulic System: The closed-center load-sensing technology ensures precise control of boom, arm, and bucket movements, with smooth and synchronized operation for high-precision excavation (e.g., foundation trench digging). The system minimizes energy loss, further enhancing fuel economy.

3. Superior Operator Comfort & Safety

- Low-Noise & Vibration-Reducing Cab: The fully sealed cab with sound insulation materials reduces internal noise to 72dB(A), creating a quiet working environment for long shifts. The air suspension seat absorbs vibration from rough terrain, significantly reducing operator fatigue.

- Intelligent Monitoring & Safety Features: The 8-inch color monitor displays real-time data including engine speed, fuel consumption, and hydraulic pressure, with fault diagnosis and alarm functions. The rearview camera and wide-angle mirrors eliminate blind spots; the emergency stop button and anti-slip cab floor ensure maximum operator safety.

- Ergonomic Control Layout: The pilot joysticks with adjustable sensitivity are positioned for effortless operation; all frequently used buttons are integrated on the joysticks, reducing the need for operator movement and improving work efficiency.

4. Durability & Easy Maintenance

- Reinforced Structural Design: The main frame, boom, and arm are welded with high-strength steel plates; the bucket is equipped with replaceable wear-resistant teeth, extending service life by 20% under heavy use. The reinforced track frame and idler can withstand impact from rocks and uneven ground.

- Easy Maintenance Access: All service points (engine oil filter, fuel filter, hydraulic oil filter) are centrally located at the rear of the machine, accessible from ground level without the need for special tools. Maintenance intervals are extended to 500 hours, reducing downtime and maintenance costs.

- Global After-Sales Support: Doosan has 200+ authorized service centers and 15 regional parts warehouses worldwide (Singapore, Dubai, Johannesburg, etc.). Spare parts can be delivered within 7-15 days; on-site technical support is available within 72 hours in major cities across emerging markets.

Typical Application Scenarios

- Urban Construction: Foundation excavation for high-rise buildings, basement construction, and pipeline laying projects.

- Road & Bridge Construction: Roadbed earthmoving, slope cutting, and bridge abutment excavation for highway and railway projects.

- Quarry & Mining Operations: Rock crushing, overburden removal, and ore loading in small-to-medium-sized quarries.

- Disaster Relief & Emergency Work: Debris clearing, river dredging, and temporary road construction in post-disaster areas.

Foreign Trade Service Guarantee

- Customization Options: Optional reinforced rock bucket, hydraulic breaker, long-reach arm (12m), air-conditioned cab (enhanced cooling for hot climates), and multilingual operation manuals (English/Arabic/Bahasa Indonesia).

- Inspection & Certification: Pre-shipment SGS/BV third-party inspection; provision of Certificate of Origin (CO), CE certification, emission compliance reports, and customs clearance documents tailored to target markets (UAE, Saudi Arabia, Indonesia, Nigeria, etc.).

- Warranty & Training: 1-year global warranty for core components (engine, hydraulic system, undercarriage); free on-site operator training covering operation, maintenance, and safety protocols in local languages.

- Spare Parts Supply: Consignment stock service for bulk buyers (construction companies, rental fleets); 24/7 online technical support for remote troubleshooting.

Why Choose DOOSAN DX225LC-9C?

The DOOSAN DX225LC-9C is the ideal 22.5-ton excavator for emerging market construction projects, combining Doosan’s proven engineering technology with high operational efficiency and low maintenance costs. Its powerful digging force and versatile attachment compatibility meet the needs of diverse construction tasks, while the fuel-efficient engine and durable design ensure long-term, worry-free operation. Backed by Doosan’s global after-sales network, this excavator delivers maximum return on investment for construction enterprises and rental fleets.

Contact Us

For real-time quotes for new/used DOOSAN DX225LC-9C excavators, attachment customization, or multilingual operator training programs, contact our dedicated sales team. We offer bulk order discounts and customized maintenance contracts for large-scale infrastructure projects.

Leave Your Message

Write your message here and send it to us