CAT 140H

Short Description:

Product Detail Page: CAT 140H Motor Grader (For Foreign Trade)Brand & ModelBrand...

- Operating Weight (Basic): 14,677kg (32,357lb); Front Axle: 4,138kg (9,123lb); Rear Axle: 10,539kg (23,234lb)

- Engine Model: Caterpillar 3176C DITA ATAAC VHP (6 - cylinder, turbocharged diesel)

- Displacement: 10.3L (629cu in)

- Rated Power: 123kW (165hp) / 2000rpm (Gears 1-2); 138kW (185hp)/2000rpm (Gears 3-8)

- Transmission: Power - shift, 8 forward / 6 reverse gears

- Max Forward Speed: 44km/h (27.4mph)

- Max Reverse Speed: 34.7km/h (21.6mph)

- Moldboard Width: 3,658mm (12ft)

- Moldboard Height: 610mm (24in)

- Max Blade Lift: 407mm (16in)

- Max Cutting Depth: 560mm (22in)

- Wheel Lean Angle: 18°

- Total Oscillation: 32°

- Overall Length: 8,173mm

- Overall Width: 2,464mm

- Overall Height (Transport): 3,131mm

- Front - Rear Axle Wheelbase: 6,169mm

- Ground Clearance: 344mm

- Turning Radius: 7.5m (24.6ft)

- Fuel Tank Capacity: 397L (105gal)

- Hydraulic Oil Capacity: 80L (20.8gal)

- Cooling System Capacity: 38L (10gal)

- Main Hydraulic Pump Flow: 206L/min

- Main Hydraulic Pressure: 241.5bar (24,150kPa)

- Hydraulic System Type: Axial - piston pump, closed - center

- Emission Compliance: EPA Tier II

Product Detail

Product Tags

Product Detail Page: CAT 140H Motor Grader (For Foreign Trade)

Brand & Model

Brand: CAT (Caterpillar) – A world-leading American construction machinery brand with a 90-year history, ranking top 1 in the global motor grader market share. CAT 140 series graders hold a 25% market share in the medium-heavy segment across the Middle East, Africa and Southeast Asia, with a service network covering 200+ countries (including 420+ authorized service centers and 12 regional parts warehouses in emerging markets). The brand’s 3176C high-pressure common rail engine and direct-drive powershift transmission are renowned for durability and precision control, making its equipment a preferred choice for road construction, mining road maintenance and airport ground leveling in high-temperature, high-dust environments.Model: CAT 140H – A 16-17 ton class medium-heavy motor grader, a classic model of CAT’s 140 series optimized for road grading, earthmoving and municipal infrastructure projects. Powered by the CAT 3176C DITA ATAAC VHP turbocharged 6-cylinder diesel engine (138kW rated power at 2000rpm) and equipped with an 8-forward/6-reverse direct-drive powershift transmission, it delivers a standard operating weight of 14,667-16,500kg, a 3.66m moldboard (extendable to 4.26m), a maximum blade lift of 407mm and a minimum turning radius of 7.5m. It meets EPA Tier 2/EU Stage II emission standards, and has been proven to operate continuously for over 15,000 hours without major failures in Middle Eastern highway construction projects, widely used in Africa, Southeast Asia and the Middle East for its low fuel consumption and precise grading performance.

Detailed Real Shots (Showcasing Equipment Status)

① Overall Appearance: Robust & Flexible

With an overall length of 8,310-9,750mm, width of 2,700mm and minimum turning radius of 7.5m, the CAT 140H has a robust and flexible body. The anti-corrosion CAT yellow paint resists salt spray in coastal construction areas and sand abrasion in desert road projects, while the 3.66m moldboard ensures efficient grading of wide roads.

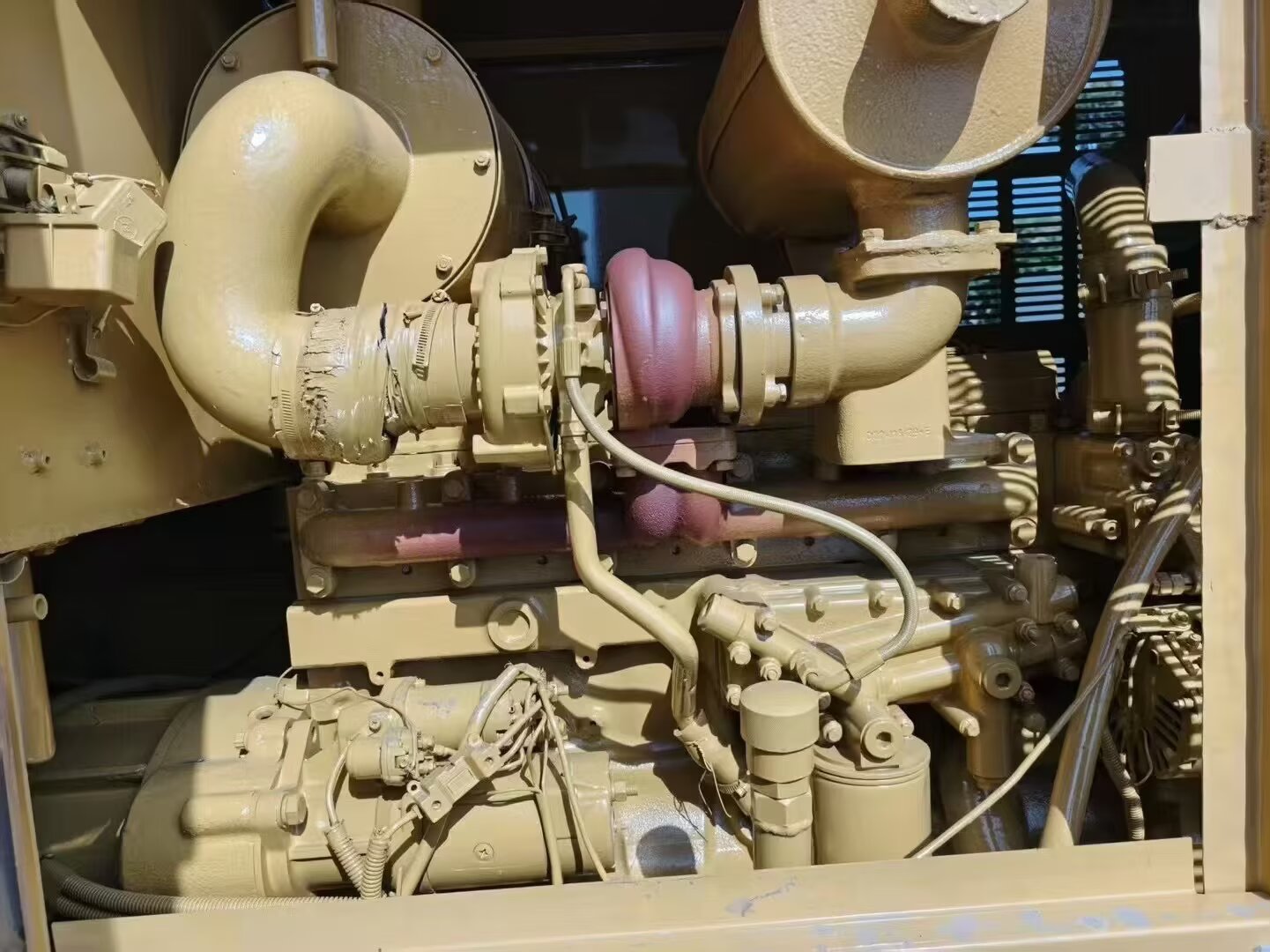

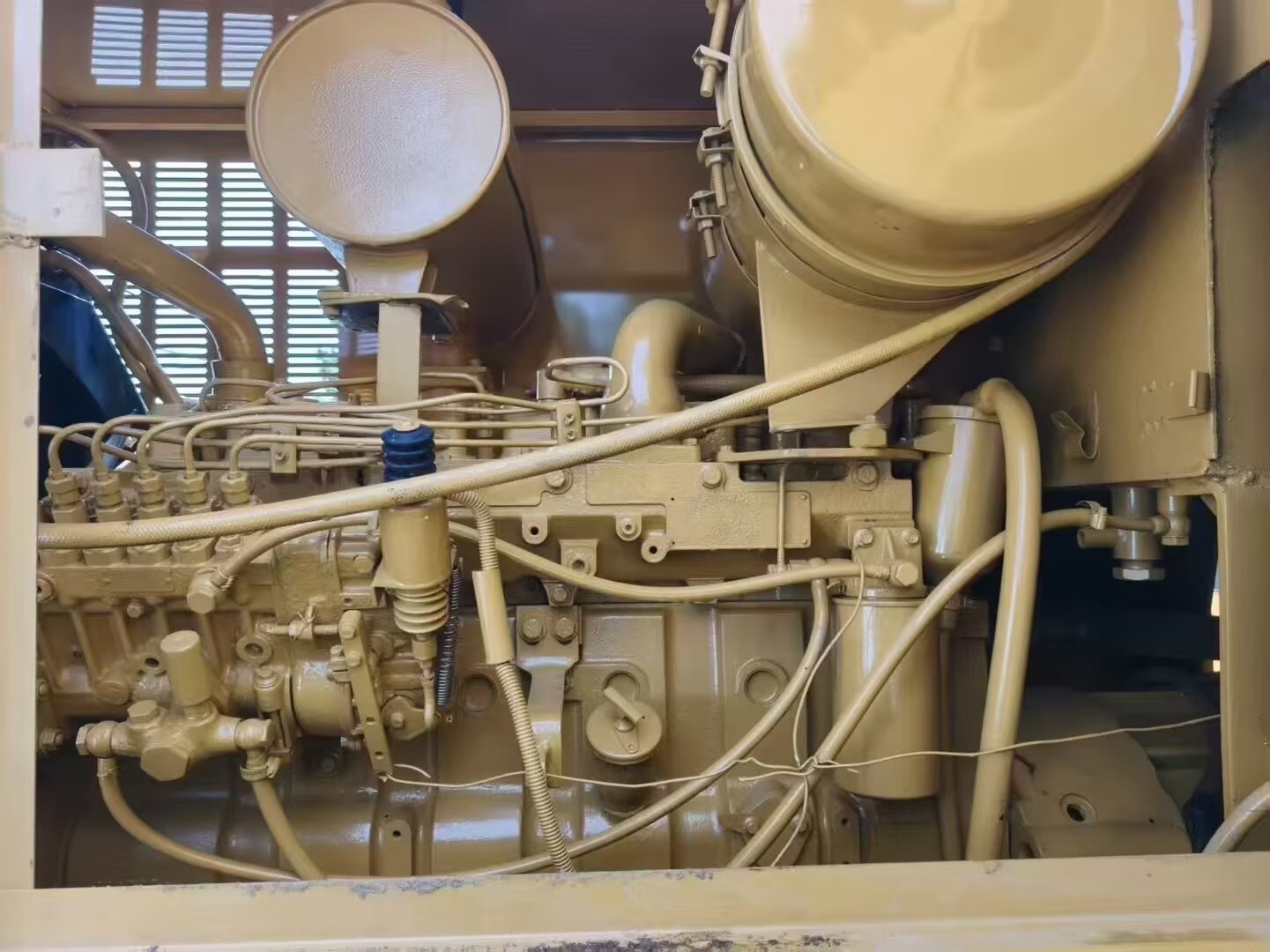

② Engine & Power System: Efficient & Reliable

The CAT 3176C turbocharged engine (138kW rated power, 10.3L displacement) is neatly arranged in a sealed engine compartment with an ATAAC air intake cooling system for efficient heat dissipation. The double-layer air filter and 390L large-capacity fuel tank adapt to harsh working conditions in emerging markets, ensuring long-term stable operation.

③ Hydraulic & Blade System: Precise & Powerful

The load-sensing hydraulic system with a main pump flow of 206L/min drives the 3.66m moldboard to achieve a maximum cutting depth of 715mm and a blade tilt angle of 40°. The reinforced moldboard made of wear-resistant steel withstands gravel impact in mining road maintenance, and the optional 3-shank ripper (maximum penetration 450mm) adapts to soil loosening operations.

④ Cab & Controls: Comfortable & Intelligent

The ROPS/FOPS certified Isomount cab reduces vibration by 30% and limits internal noise to ≤80dB, equipped with an air conditioning system and adjustable suspension seat for operator comfort in high-temperature environments. The intuitive control lever layout and wide-view windshield ensure precise operation and all-round visibility during road grading.

Core Advantages

1. High-Efficiency & Durable Power System

The CAT 140H is equipped with the CAT 3176C DITA ATAAC VHP 6-cylinder turbocharged diesel engine (138kW/2000rpm, 10.3L displacement), adopting high-pressure common rail fuel injection technology and ATAAC air intake cooling system:

- Strong Power Output: The engine delivers a maximum torque of 950N·m, ensuring efficient grading of hard-packed soil, gravel and rock mixtures in mining road maintenance, with a 70% climbing capacity to adapt to steep slopes in mountainous construction areas.

- Fuel-Saving & Eco-Friendly: The VHP (Variable Horsepower) system adjusts power output according to gear and load, reducing fuel consumption to 12-14L per working hour — 10% lower than peers in the same tonnage class. It meets EPA Tier 2/EU Stage II emission standards, perfectly adapted to emerging markets with relatively strict emission regulations.

- Dust-Resistant & Long-Lasting: The double-layer air filter with radial seals effectively blocks dust and sand in desert and mining areas, extending the engine’s service life to 16,000 hours — 25% longer than the industry average. The engine compartment adopts a sealed heat dissipation design, ensuring normal operation in high-temperature environments above 45°C in the Middle East.

2. Precise & Smooth Transmission & Hydraulic System

Paired with CAT’s direct-drive powershift transmission and load-sensing hydraulic system, the CAT 140H realizes fast travel and millimeter-level blade control:

- Seamless Shifting & High Mobility: The 8-forward/6-reverse electronic-controlled transmission enables smooth gear changes without power interruption, with a maximum forward speed of 44km/h (27.4mph) for long-distance transfer between construction sites, and a maximum reverse speed of 34.7km/h (21.6mph) for efficient backfilling operations.

- Precise Blade Control: The load-sensing hydraulic system provides a main pump flow of 206L/min and a working pressure of 24,150kPa, enabling proportional control of the blade, circle and ripper. The 40° blade tilt angle and 5° cutting angle ensure efficient material rolling and slope finishing with a flatness error of ≤3mm, meeting the strict requirements of highway and airport pavement construction.

- Low Maintenance Cost: The hydraulic oil replacement cycle is extended to 4,000 hours — twice the industry average. Sealed pivot points reduce greasing frequency by 50%, and modular hydraulic components allow quick replacement in remote overseas sites.

3. Robust Structure & Humanized Cab Design

The CAT 140H adopts a box-section high-strength steel frame and an Isomount vibration-damping cab, prioritizing operational stability and operator comfort:

- Superior Stability: The heavy-duty frame and balanced front-rear axle load (4,138kg/front, 10,526kg/rear) ensure no tipping during heavy-load ripping and high-speed grading. The 32° front-axle oscillation angle adapts to uneven ground in mining areas, and the 600mm-wide tires provide strong traction on soft soil roads.

- Comfortable & Safe Cab: The ROPS/FOPS certified Isomount cab reduces vibration by 30% and limits internal noise to ≤80dB, with an adjustable suspension seat and air conditioning system (cooling capacity 5kW) to ensure operator comfort during 8-hour+ continuous shifts. The wide-view windshield and rearview mirrors provide 360° visibility, and the hydraulic safety lock prevents misoperation during maintenance.

- Easy Maintenance: Daily maintenance points (engine oil, hydraulic oil, air filter) are accessible at ground level, cutting maintenance time by 25%. The centralized electrical control panel simplifies fault diagnosis, and common spare parts (filters, blades, seals) are available in CAT’s regional warehouses in Dubai, Singapore and Johannesburg, with a delivery time of 3-7 days.

4. Versatile Application & Attachment Compatibility

The CAT 140H supports multiple customized attachments and adapts to diverse construction scenarios:

- Optional Attachments: It can be equipped with a 3-shank ripper (maximum penetration 450mm) for soil loosening and rock breaking, a snowplow for winter road maintenance, and a scarifier for asphalt pavement renovation — expanding its application scope by 40%.

- Corrosion-Resistant Design: The anti-rust paint on the body resists salt spray corrosion in coastal port areas and chemical corrosion in mining areas, extending the equipment’s service life by 30%. The reinforced moldboard (610mm height) uses wear-resistant steel, with a service life of up to 8,000 hours in gravel grading scenarios.

Typical Application Scenarios

The CAT 140H is a versatile medium-heavy motor grader for various overseas infrastructure projects:

- Highway Construction & Maintenance: Ideal for subgrade leveling, pavement base preparation and slope finishing in Middle Eastern and Southeast Asian highway projects. Its precise blade control meets the 3mm flatness requirement for asphalt paving, and the low fuel consumption reduces operational costs for long-distance road construction.

- Mining Road Maintenance: Suitable for grading and pothole repair of mining haul roads in African and Australian mines. The powerful ripper handles compacted gravel and rock, and the high-speed transmission shortens travel time between mining areas, improving maintenance efficiency by 25%.

- Airport & Port Ground Leveling: Perfect for apron leveling, container yard construction and coastal reclamation in European and Latin American airports/ports. The 7.5m minimum turning radius enables operation in confined spaces, and the load-sensing hydraulic system ensures precise ground leveling for aircraft takeoff/landing and container handling.

- Municipal Engineering & Urban Renovation: Used for road widening, drainage construction and residential area ground leveling in African and Middle Eastern cities. The optional snowplow adapts to cold-region municipal maintenance, and the low-noise design meets urban construction noise regulations.

Foreign Trade Service Guarantee

We provide one-stop cross-border support for CAT 140H buyers:

- Comprehensive Equipment Inspection: For used units, we issue detailed test reports (engine power, hydraulic pressure, blade wear, working hours) and real-time operation videos. Third-party inspection (SGS/BV) is available to verify equipment condition for international buyers, focusing on core components such as the 3176C engine, direct-drive transmission and load-sensing hydraulic system.

- Customized Compliance Support: We assist in preparing import documents (CO, CE certificates, emission reports) tailored to local regulations in the Middle East, Africa and Southeast Asia. The CAT 140H meets EPA Tier 2/EU Stage II emission standards, ensuring smooth customs clearance in most emerging markets without modifications.

- Logistics & On-Site Commissioning: We offer Ro-Ro shipping or container transport solutions with anti-rust packaging for sea transport. Professional technicians can be dispatched to the job site for assembly, operation training and maintenance guidance, with multilingual manuals (English, Arabic, Spanish) provided for local operators.

- Global Spare Parts & After-Sales: Leveraging CAT’s overseas parts warehouses (Dubai, Singapore, Johannesburg), common spare parts (filters, blades, hydraulic hoses) are delivered within 3-10 days to overseas sites. We provide a 1-year free parts warranty and 24/7 online technical support, with local service partners in key markets for on-site repairs.

Why Choose CAT 140H?

The CAT 140H integrates American heavy-duty machinery technology with global road construction demands, making it a star product in the medium-heavy motor grader segment for overseas projects. Its 3176C engine delivers 10% lower fuel consumption than competitors, and the 8-speed transmission improves travel efficiency by 20%. For road contractors, mining operators and municipal engineering teams in the Middle East, Africa and Southeast Asia, the CAT 140H offers a low total cost of ownership — with 16,000-hour continuous operation without major failures and easy access to spare parts — ideal for road construction, mining maintenance and airport projects requiring precision and durability.

Contact Us

If you need detailed fuel consumption data of the CAT 140H, real-time quotes for new/used units, customized attachments (e.g., ripper, snowplow) or operation training for precise grading, contact our team now. Let the CAT 140H power your overseas road and infrastructure projects with unmatched performance!

Leave Your Message

Write your message here and send it to us