XCMG LW300FN

Short Description:

Product Detail Page: XCMG LW300FN Wheel Loader (For Foreign Trade)Brand & ModelB...

Product Detail

Product Tags

Product Detail Page: XCMG LW300FN Wheel Loader (For Foreign Trade)

Brand & Model

Brand: XCMG (Xuzhou Construction Machinery Group) – A leading Chinese construction machinery manufacturer with a global footprint spanning 187 countries, renowned for its cost-effective, rugged equipment tailored to emerging market needs. XCMG loaders dominate the 3-ton segment in Asia, Africa and Latin America, with a 20+% market share in the global mid-sized loader category. The brand’s overseas service network includes 300+ authorized service centers and 5 regional parts warehouses, ensuring fast support for users in remote construction sites.Model: XCMG LW300FN – A 3-ton class medium wheel loader, the best-selling single model in the global 3t loader segment and an upgraded iteration of XCMG’s classic ZL30E. Powered by the Yuchai YC6B125-T21 engine (92kW rated power) and paired with a fixed-shaft power shift transmission, it delivers a maximum breakout force of 130kN and traction force of ≥90kN. With a 2600mm wheelbase and 5165mm minimum turning radius, it balances maneuverability and load capacity, making it ideal for port cargo handling, urban construction and mine auxiliary operations. It is particularly popular in Southeast Asia, Africa and Eastern Europe for its adaptability to harsh working conditions and low maintenance costs.

Core Advantages

1. High-Efficiency Power & Drive System

The LW300FN is equipped with the Yuchai YC6B125-T21 6-cylinder diesel engine (92kW/2300rpm), which meets China National II emission standards and features a high torque reserve coefficient to handle sudden overloads during heavy-load operations. The engine’s large air filter and reinforced cooling system ensure stable performance in dusty mining areas and high-temperature tropical climates (up to 45°C). Paired with a three-element torque converter and fixed-shaft power shift transmission (4 forward/2 reverse gears), the loader achieves 35km/h maximum speed and efficient power transfer, reducing fuel consumption by 8% compared to conventional 3t loaders. The heavy-duty drive axle with 35° swing angle adapts to uneven terrain, while international standard drive shaft flanges enhance torsion resistance for continuous high-intensity work.

2. Optimized Working Device for High Productivity

The LW300FN’s working device is engineered for maximum loading efficiency and durability:

- High-Performance Bucket: The 1.8m³ standard bucket (expandable to 2.4m³) uses high-strength wear-resistant steel with a lengthened bucket bottom and sharpened edge, reducing insertion resistance by 15% and increasing bucket filling rate to 95%. Optional rock buckets, coal buckets or clamps adapt to bulk material handling, wood grabbing and rock loading scenarios.

- Strong Lifting Capacity: The U-shaped beam structure of the boom and arm delivers a maximum lifting force of 130kN and unloading height of 2930mm, ideal for loading 10t trucks and port cargo containers. The working device’s three-action cycle time is only 11 seconds, boosting loading efficiency by 20% in bulk material operations.

- Structural Durability: The frame and working device are designed with finite element analysis to eliminate stress concentration, while the welded U-shaped crossbeam enhances structural rigidity for long-term use in rock and gravel handling.

3. Maneuverability & Adaptability to Complex Work Sites

With a 2600mm wheelbase and 5165mm minimum turning radius (tire center), the LW300FN excels in narrow spaces like ship cabins, urban construction sites and small mines:

- High Mobility: The 17.5-25-12PR tires and 28° maximum climbing capacity enable stable operation on muddy construction sites and steep mine ramps.

- All-Condition Adaptability: The sealed electrical connectors and waterproof fuse box prevent short circuits in rainy tropical regions, while the reinforced undercarriage resists abrasion from sand and gravel in desert areas.

- Diversified Attachments: Optional clamps, hay grapples and fork attachments extend its use to agriculture, waste management and warehouse logistics, meeting the multi-scenario needs of overseas users.

4. Comfortable Cab & Easy Maintenance

The LW300FN prioritizes operator comfort and low maintenance costs for long-hour overseas operations:

- Ergonomic Cab: The full-metal molded cab features sound insulation and optional air conditioning (cooling capacity 5kW), reducing interior noise to ≤78dB and adapting to extreme temperatures from -10°C to 45°C. The adjustable suspension seat and centralized control panel minimize operator fatigue during 10+ hour shifts, while the seamless glass design provides 360° visibility for safe operation in crowded ports.

- Simplified Maintenance: The hydraulic system’s centralized pressure test points and ground-level access to daily checkpoints (oil level, coolant, air filter) cut maintenance time by 30%. Key components like the transmission and torque converter have a service life of 5,000 hours, and the front/rear frames come with a 2-year/5,000-hour warranty—far exceeding industry standards.

- Durable Components: The fuel tank (160L) and hydraulic oil tank (100L) use corrosion-resistant steel, and the imported waterproof electrical connectors reduce failure rates by 40% in humid coastal areas.

Detailed Real Shots (Showcasing Equipment Status)

① Overall Appearance: Compact & Rugged

With transport dimensions of 7050mm×2482mm×3025mm and a net weight of 10,000kg, the LW300FN is compact enough for ship cabin operations and port cargo handling. The anti-corrosion paint and reinforced counterweight resist salt spray in coastal ports and sand abrasion in desert mines, while the full fender design prevents gravel from splashing and damaging the engine compartment.

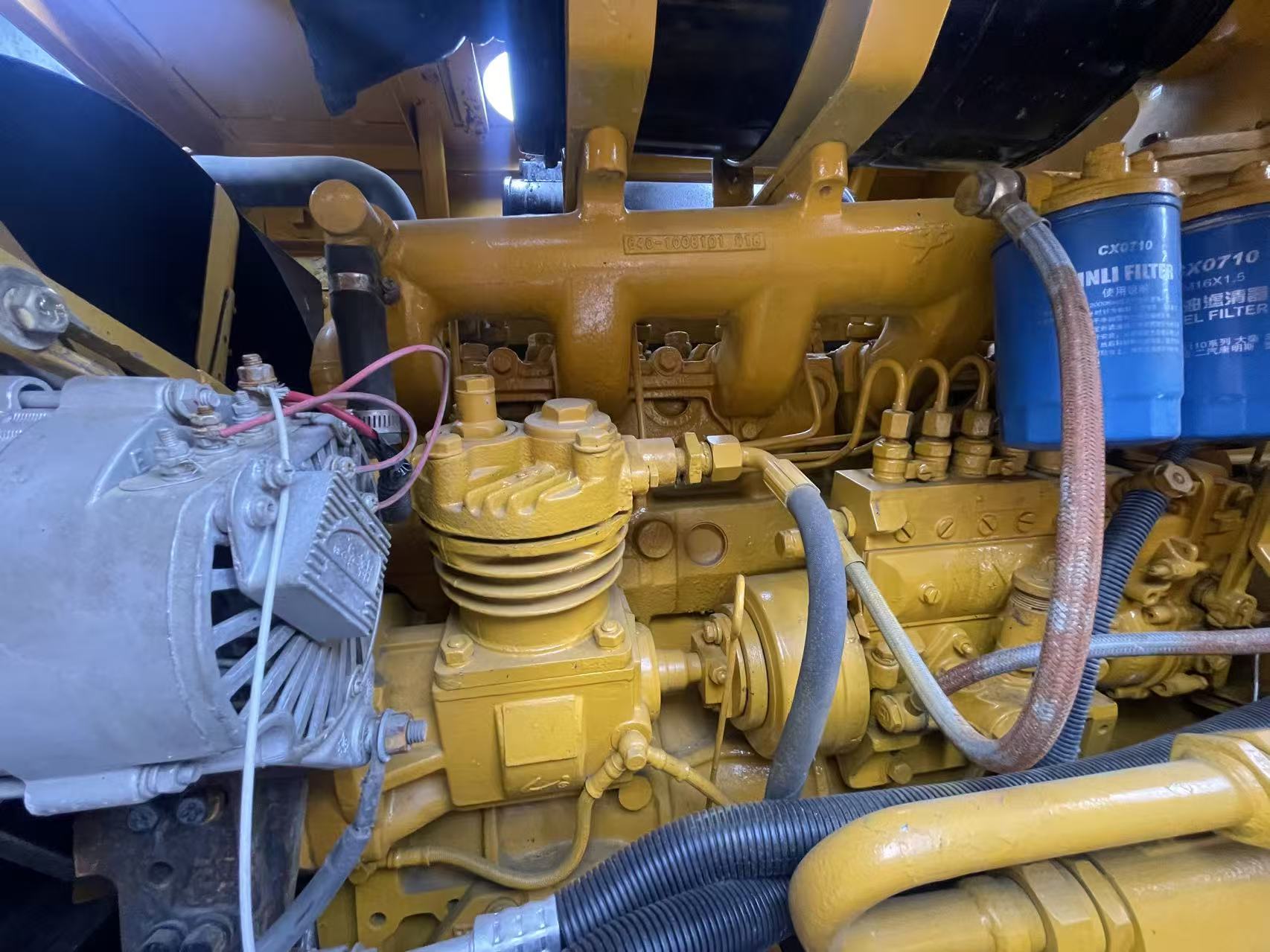

② Engine & Transmission: Reliable & Fuel-Efficient

The Yuchai YC6B125-T21 engine and fixed-shaft transmission are neatly arranged in a sealed engine compartment with a large-capacity radiator for efficient heat dissipation. The double-layer air filter system prevents dust from entering the engine—critical for mining in Africa’s arid regions—while the centralized oil filter design allows quick replacement without special tools.

③ Bucket & Working Device: High-Capacity & Durable

The 1.8m³ U-shaped bucket with wear-resistant steel teeth delivers 130kN breakout force, easily penetrating hard soil and gravel piles. The WC-sprayed pin connections reduce wear by 30% in rock handling, while the 2930mm unloading height is perfect for loading 3t-5t trucks in construction sites and ports.

④ Cab & Controls: Intuitive & Comfortable

The spacious cab features an ergonomic joystick, centralized instrument panel and optional air conditioning, reducing operator fatigue during long shifts in tropical regions. The large front/rear windows provide unobstructed visibility for safe operation in narrow ship cabins, while the waterproof switches and dustproof seat cover adapt to harsh working environments.

Typical Application Scenarios

The XCMG LW300FN, with its versatility and cost-effectiveness, is the go-to choice for small-to-medium overseas projects:

- Port Cargo Handling: Its 2600mm wheelbase and compact size make it ideal for clearing ship cabins and loading bulk cargo (grain, ore) at international ports in Eastern Europe and Southeast Asia. The high bucket filling rate ensures efficient cargo turnover, avoiding delayed ship schedules.

- Urban Construction & Infrastructure: Suitable for road construction, building demolition and material handling in city projects. The low fuel consumption and maneuverability reduce operational costs in densely populated urban areas, while the reinforced bucket handles concrete debris and gravel loading.

- Mine Auxiliary Operations: Used for transporting ore, cleaning mine sites and feeding crushers in small-scale gold, coal and limestone mines in Africa and Latin America. The heavy-duty drive axle and high traction force adapt to uneven mine terrain, and the easy maintenance design minimizes downtime in remote mining areas.

- Agriculture & Logistics: With optional hay grapples or forks, it can handle crop harvesting, feed mixing and warehouse cargo stacking in rural areas of Southeast Asia and South America, meeting the multi-functional needs of small and medium-sized enterprises.

Foreign Trade Service Guarantee

We provide one-stop cross-border support for overseas buyers of the XCMG LW300FN, addressing all procurement challenges from inspection to after-sales:

- Comprehensive Equipment Inspection: For used LW300FN units, we issue detailed test reports (engine power, hydraulic pressure, tire wear, working hours) and real-time operation videos. Third-party inspection (SGS/BV) is available to verify equipment condition for international buyers, with a focus on key components like the transmission and bucket wear.

- Customized Compliance Support: We assist in preparing import documents (CO, CE certificates, customs clearance papers) tailored to local regulations in Africa, Southeast Asia and Latin America. The LW300FN meets non-road emission standards for most emerging markets, ensuring smooth customs clearance without additional modifications.

- Logistics & On-Site Commissioning: We offer Ro-Ro shipping, container transport or bulk cargo solutions with anti-rust packaging for sea transport. Professional technicians can be dispatched to the job site for equipment assembly, operation training and maintenance guidance, with multilingual manuals (English, Spanish, Arabic) provided for local operators.

- Global Spare Parts & After-Sales: Leveraging XCMG’s overseas parts warehouses (Dubai, Lagos, Jakarta), common spare parts (filters, bucket teeth, hydraulic hoses) are delivered within 7-15 days to overseas sites. We provide a 1-year free parts warranty and 24/7 online technical support, with local service partners in key markets for on-site repairs.

Why Choose XCMG LW300FN?

The XCMG LW300FN combines XCMG’s decades of loader expertise with cost-effective design, making it the top choice for mid-sized overseas projects. Its Yuchai engine and fixed-shaft transmission deliver reliable performance in harsh environments, while the 130kN breakout force and 1.8m³ bucket ensure high productivity in loading and material handling. For small and medium-sized enterprises in Africa, Southeast Asia and Latin America, the LW300FN offers a low total cost of ownership—with 30% lower maintenance costs than European brands and 15% higher fuel efficiency than comparable Chinese models—ideal for budget-conscious projects requiring versatile equipment.

Contact Us

If you need detailed technical parameters of the LW300FN (e.g., fuel consumption, hydraulic system pressure), real-time quotes for new/used units, customized attachments (e.g., rock buckets, clamps), or spare parts procurement channels, contact our team now. Let the XCMG LW300FN power your overseas construction, port and mining projects with unmatched value and reliability!

Leave Your Message

Write your message here and send it to us